SERVICES

UV-Cured GRP CIPP Lining

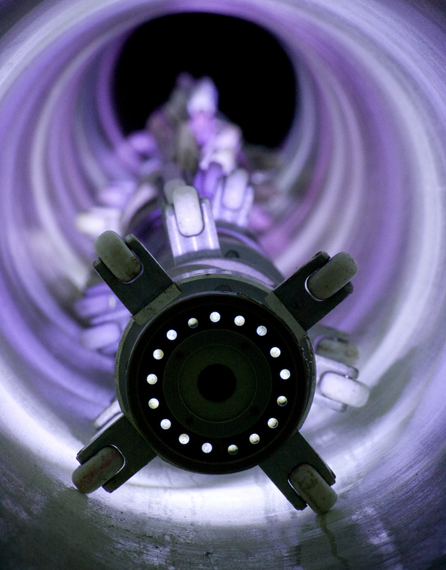

ABEL RECON offers comprehensive pipe relining solutions for underground sanitary and stormwater infrastructure rehabilitation needs. Our certified team of project managers and field personnel can reinstate new life to your aging and deteriorated pipelines, with the use of Alphaliner™, manufactured by Reline America. This spirally wound fiberglass tube is resin-impregnated, pulled into a failing pipe, expanded, and cured with UV light to form a fully structural pipe inside the host pipe.

When the Alphaliner GRP lining process is fully completed, it restores full structural integrity and renewed watertightness to the once-failing host pipe. The UV resin curing process for the fiberglass composite allows us to install the GRP/UV liner with less disruption, and in a shorter time frame, than conventional lining materials. This means ABEL RECON can install, cure and reinstate lateral services more quickly, resulting in less disturbance for the asset owner and utility customers. There is also no danger of toxic fumes or off-gassing found with some other resin-curing methods.

The Alphaliner material and installation equipment are both manufactured domestically for the North American market at Reline America’s Saltville, Virginia campus. All liner “wet-out” is performed at this ISO-certified facility, assuring quality and consistency. With sizing capabilities for pipes ranging from 6-inch to 72-inch diameters and of any geometric shape, the liner product arrives at the project location ready to install. It can also be stored up to six months without refrigeration.

Sanitary Sewer Structure Rehabilitation

With much of America’s underground infrastructure reaching or having already surpassed its design life, many people are recognizing the immediate need for authorities and municipalities to rehabilitate their water/wastewater infrastructure. One of the most critical segments of this network are sanitary sewer collection system structures. One of their most significant problems is excess flow volumes, caused by unwanted inflow and infiltration (I/I). In fact, it was the growing need to rehabilitate these collection and sewer access structures that first prompted our entry into the infrastructure rehabilitation arena.

We immediately embraced Sprayroq® spray-applied polyurethane, cured-in-place polymer systems. These systems possess unmatched physical strengths, and their application employs thorough, effective QA/QC measures to get the job done right the first time. ABEL RECON is a Sprayroq Certified Partner, meaning we’re part of a group of intensively trained contractors specializing in the repair and rehabilitation of many types of host materials, structure sizes and configurations, including:

- Pipes (Sanitary, Storm, Industrial Process)

- Manholes

- Wet wells / Lift stations

- Clarifiers

- Tanks & Vaults

- Large diameter sanitary sewer and stormwater culverts

- Secondary containment structures

Storm Drainage Infrastructure Remediation

State and Municipal Highway Departments

ABEL RECON also employs the Sprayroq and Reline America systems for stormwater asset work. This service is most often used on rural, low-volume roads and state highway applications such as under-highway stream bed crossings, culverts, roadway drainage collection pipes and inlets.

We understand that our field expertise and knowledge is often required to assist in the underground storm structure condition and evaluation process before this work can be specified. Our trained, experienced teams stand ready to perform asset cleaning, remote CCTV inspection, and expert design and project scope recommendations. Our complete package of services saves you time and gives you confidence at every stage of the project.

Sustainable Wastewater Solutions

ABEL RECON is the licensed service provider for EnBiorganic Technologies autonomous microbial formulation system, the EBS-Di. The EBS-Di is a compact, one platform, microbial formulation system that will adapt, activate, multiply, and dispense highly concentrated microbiology into your collection system.

Our sustainable solution helps wastewater treatment plants reduce compliance issues, excessive sludge management costs, odor issues, capacity limits, infrastructure deterioration, aeration energy costs, and problems related to FOG. ABEL RECON provides the customer service and maintenance for the EBS-Di system, ensuring maximum operations and client satisfaction. Together, ABEL RECON and EnBiorganic Technologies guarantee wastewater treatment plant improvements in effluent quality and operational cost savings.

Alternative Procurement and Project Funding

We understand that procurement budgets and grant monies are limited, but underground asset rehabilitation can only be put off for so long before its neglect causes even more expensive and disruptive issues. That’s why we’ve become expert consultants to our clients in helping procure alternative funding sources when traditional avenues are unavailable. We can help you understand and navigate through several alternative funding programs such as Public, Private, Partnership (P3) funding, or your state sponsored co-operative purchasing program.

P3 funding uses private capital for low interest/long term loans that are available to any municipality. These programs add the stability for extending the cost of funding large projects or upgrades. Co-operative purchasing programs such as COSTARS for Pennsylvania and the ODOT cooperative purchasing program for Ohio are just two examples of state approved purchasing contracts. These allow municipalities to select pre-tested and pre-approved products without going through the resource dependent bidding process.

ABEL RECON not only is a participant in our local co-operative purchasing programs, but it also has the resources, knowledge, and experience to act as your partner in facilitating an alternative funding mechanism. Don't put that big project off any longer.

COSTARS Participant

ABEL RECON is a certified COSTARS member and installer for the Commonwealth of Pennsylvania's cooperative purchasing program. Any registered and eligible local public procurement units or state-affiliated entities are able to purchase our rehabilitation products though the purchasing program. These contracts established by Department of General Services are designed to provide smaller municipalities the opportunity to complete projects without having to go through long and resource dependent bid solicitation process. Let ABEL RECON solve your storm water or wastewater problem for you!